Unleashing Innovation with Intricate CNC Machining

October 11,2025

Introduction: CNC machining has evolved beyond traditional manufacturing methods, enabling the creation of highly precise, complex parts that drive growth across multiple industries. Whether you specialize in aerospace, electronics, or product design, you’ll find CNC machining to be a cornerstone of innovation. Here, we explore how modern CNC techniques bring intricate geometries to life and shape the next generation of high-performance components.

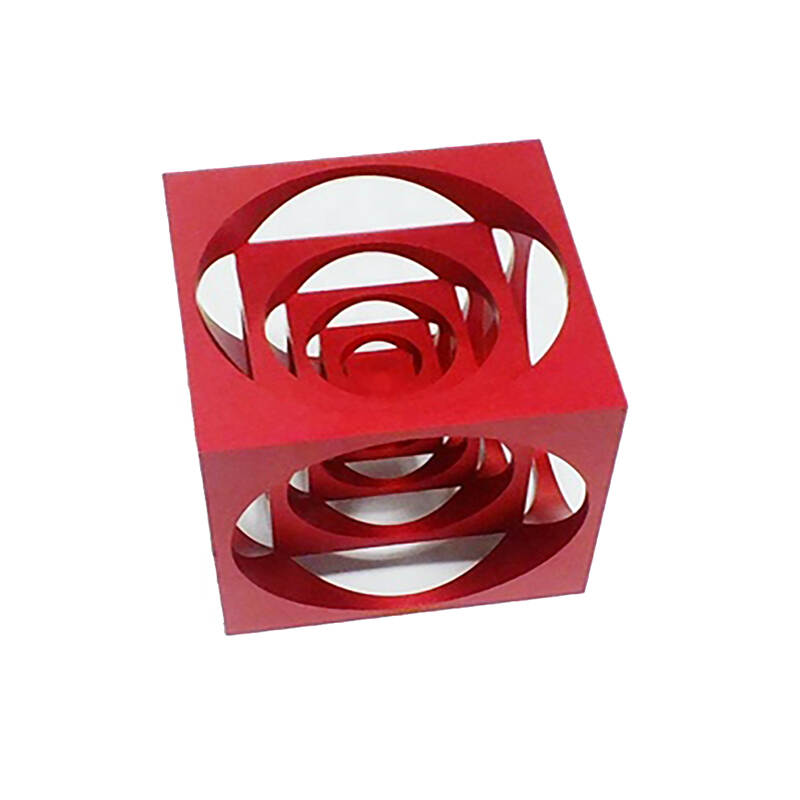

One striking example of complex design made possible through CNC machining is seen in the eye-catching cubical structure below, featuring meticulously drilled circular layers and smooth edges:

1. Precision Engineering for Complex Geometry

When dealing with elaborate designs such as concentric circular openings or multi-layered structures, CNC machining excels at achieving exceptional precision. By following programmed instructions with sub-millimeter accuracy, CNC machines can navigate complex geometries without sacrificing structural integrity. Parts that would otherwise be impossible or prohibitively expensive to create now become feasible with the right CNC setup.

2. High-Quality Surface Finishes

Beyond shaping metal or other materials into complex forms, CNC machining also refines surfaces for aesthetic and performance needs. Whether it’s ensuring aerodynamic efficiency or simply refining the look of a visually striking component, CNC tools and software handle intricate detailing to prevent burrs, ridges, and surface inconsistencies.

3. Seamless Integration into Diverse Industries

From automotive to medical devices, almost every leading industry leans on CNC machining for customized components. For instance, in consumer electronics, precisely milled cases and internal brackets enable compact, sophisticated product designs. Meanwhile, in automotive engineering, CNC-made prototypes accelerate product development and enhance safety testing by ensuring accuracy and strength.

4. Flexible Production Capabilities

One of the strongest advantages of CNC machining is its adaptability to various production volumes. Small batches benefit from the quick setup, while large-scale projects profit from consistent replication. This versatility allows businesses to respond swiftly to changing demands or sudden production ramp-ups, eliminating the need for expensive retooling or compromised quality.

5. Reduced Production Time and Cost-Effectiveness

Modern CNC machines operate with advanced software that minimizes operational errors and idle time. Although programming CNC equipment may require a specialized skill set, the overall reduction in manual labor and resources translates into cost savings. This reliability, combined with high repeatability, turns CNC machining into a financially viable solution for both small and large manufacturing projects.

6. Embracing Advanced Materials

Metals like aluminum, steel, and titanium are well-known in CNC applications, but the technology also accommodates plastics, composites, and high-temperature alloys. By leveraging the right tools, feed rates, and cutting parameters, you can produce robust prototypes or end-use parts with tight tolerances in materials that suit unique industry requirements.

Conclusion

CNC machining’s versatility, accuracy, and ability to craft intricate shapes continue to make it indispensable across today’s manufacturing landscape. From prototyping complex geometric designs to optimizing mass production, CNC’s evolution opens new possibilities for engineers and innovators worldwide.

Looking to partner with industry experts for high-quality CNC machining? 深圳市基石恒晟科技有限公司 (Shenzhen Jishihengsheng Technology Co., Ltd.) offers a full range of CNC machining services, including lathe milling, milling parts processing, and sheet metal parts fabrication. With 51–100 employees, an 80% export ratio, and an average lead time of just 15 days, we are well-positioned to deliver top-tier solutions to our clients in Europe, America, and beyond. For more information, visit our official website: http://www.jshs-cnc.com or contact us via phone at 13602584991 or email at simonwu@jshs-cnc.com.